Special gearboxes - power supply systems on railway carriages

Power supply from the wheelset axle is the most cost-effective solution that enables the vehicles to be used freely, regardless of the type of traction. We have been developing, designing and manufacturing gearboxes for power supply systems on railroad cars for almost 70 years. To date, a total of approximately 30,000 gearboxes have been delivered to 26 different countries with a wide variety of climatic and installation conditions.

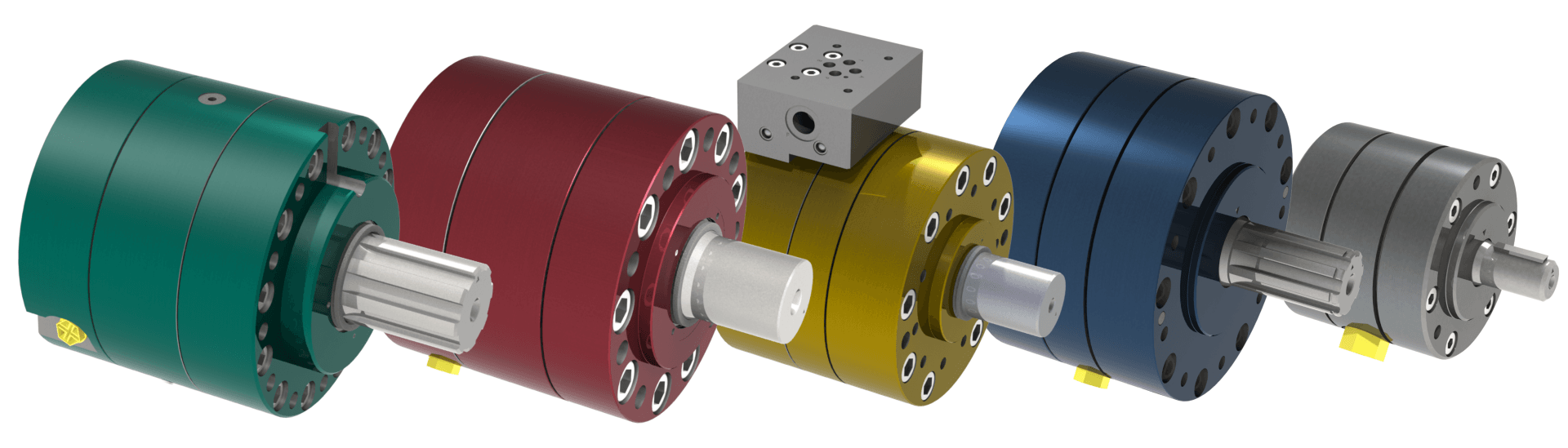

Different gearboxes were developed specifically for the generators of the companies AEG, BOSCH, EVR, SIEMENS and STONE, whereby some of the rotors are attached directly to the gearbox shaft (AEG, BOSCH, EVR) and the generators therefore do not need their own bearings.

The development of heavy-duty worm gears or the use of spiral-toothed bevel gears resulted in light and powerful gears, the speed ranges of which allow considerable applications. This means that it can be used on high-speed passenger coaches up to 200 km / h as well as on refrigerated, packing or other special wagons that sometimes require electrical power from 15-20 km / h driving speed.

The installation of highly flexible couplings between the gearbox and axle set, labyrinth seals between the gearbox and generator and homokinetic cardan shafts for driving heavy generators are our standard. We can base our findings on our own extensive measurements and tests and make extensive statements about the torsional vibration behavior of these ultra-modern systems.

The installation, testing, maintenance and repair instructions specially drawn up for each customer enable trouble-free handling of our gearboxes.

We develop customized solutions for the installation of power supply systems on the axle bearing of rail vehicles or new gears for suitable generators.